The console is mainly used in large command and control center, monitoring center and other working environments. Due to the continuous work for 7*24h, rational arrangements shall be made for the durability and comfort of the console and harmony of the working environment. The top of the console and the place bedside the keyboard bracket are the more usual places for the operator to contact and the side plate is one of the major decorations of the console, so the selection on these materials is extremely important. Except the environmental protection performance of the materials, more attention should be paid to comfort, durability and beautiful appearance. Furthermore, coordination between the board color and the working environment also should be focused. In view of this, we provide three materials for selection: medium density fiberboard, compact board and artificial stone; and simultaneously, we will provide professional suggestions for you based on your working environment.

The medium density fiberboard, a kind of density board, pertains to the E1 Dare medium density fiberboard. Adopting wood fiber or other plant fibers as the raw materials, it is the artificial board that is made through hot-pressing after crushing the materials, fiber separation, drying and applying urea resin or other applicable adhesives. Three ways are available to process the surface layer of the medium density fiberboard, including painting, sticking wood veneers and pressing decorative refractory slab.

Choose the imported PU high-grade polyester paint to paint on the surface of the medium density fiberboard. With primer, lacquer and roast under high temperature, no scratch and impurity as well as uniform color of the painted surface can be guaranteed.

- White sand

- Silvery white

- Silvery grey

- Black silver pearl

- Sony grey

- Blue flash

- Grid green

- Black imitation leather

Sticking wood veneers on the surface of the medium density fiberboard is more and more popular in office furniture because of the lacking in forest resources and rising price in solid wood materials. For office furniture exhibition in Dongguan, Shenzhen, Guangzhou and other places in 2007, the furniture with wood veneers on the surface were sold soundly and took a lead in furniture industry. Wood veneer sticking technology has the advantages of beautiful texture, strong sense of reality and low cost. Wood veneer stuck material refers to the medium density fiberboard with the wood veneers on the surface. The wood veneers are the first-grade natural wood veneers free of dead knot, rotten, white edge, excessive mineral lines and other defects.

- Red teak

- Walnut

- Walnut (light yellow)

- Cherry

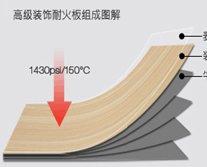

Pressing decorative refractory slab in a hot manner on the surface of the medium density fiberboard refers to choosing Formica and Wilsonart high-grade decorative refractory slab which has passed CNS11366 and CNS11367 standard. With the excellent characteristics of moisture resistance, heat resistance, scratch resistance, smoke resistance, no mildew, easiness in cleaning and long service life, it is awarded as “Green Building Material” and is named as the actual environment-friendly material. The high-grade decorative refractory slab is manufactured by high-grade decorative paper and high-grade kraft paper by soaking, drying and processing at high temperature and pressure and a plurality of designs and surface treatments are available for you to select.

- 0459 Bright white

- 0932 Lotus white

- 7938 Glacier

- 0927 Morning grey

- 0928 Mouse grey

Artificial stone is a newfashioned DuPont Montelli composite material and is made by certain processed produce through the mixture of unsaturated polyester resin, filler and pigment and the addition of few initiators. The stone is bright and colorful as well as similar to the natural marble by adding different pigments during manufacturing. The artificial stone has the advantages of no toxicity, no radioactivity, fire resistance, oil resistance, stain resistance, bacteria and mold resistance, wear resistance, impact resistance, easiness in maintenance, seamless splicing and convenience in modeling, etc. The product is characterized by light weight (compared with natural stone material), high hardness, oil resistance, stain resistance and corrosion resistance. At the same time, the board has uniform thickness, nice glossiness, obvious light transmission effect, no deformation, fireproofing, ageing resistance, no radiation and penetration resistance, etc. Furthermore, the stone can be bent freely as per requirements of the customer with the seamless splicing, thus the highest quality can be truly reached.

Framework is of importance to the stability of the console and each console’s structure of ours has its uniqueness. For the framework, cold-roll steel sheets and high-intensity aluminum profiles are available mainly. Surely, we will select the framework material reasonably based on the working environment. As of the framework of the cold-roll steel sheets, different colors can be chosen to coordinate with the table board, lateral plate and working environment.

- White sand

- 7035

- Grey sand

- White crumple

- Silver grey

- Sony grey

- Black textured